الحار منتجات

ملكنا الإخبارية

parts grinding production

A hybrid approach of case-based reasoning and process

2023年1月19日 After grinding, the machine tool spindle with high surface integrity has a significant impact on its subsequent service life. Therefore, it is necessary to create a reasonable process plan for the grinding process of the machine tool spindle. A hybrid

Strategies for production of parts textured by grinding

2013年1月1日 Basically, the production of textured workpieces is realized by using a patterned grinding wheel and integer angular speed ratio between workpiece and wheel

Grinding/Cutting Technology and Equipment of Multi

2022年7月28日 Multi-scale casting parts are important components of high-end equipment used in the aerospace, automobile manufacturing, shipbuilding, and other industries.

Manufacturing Miniature Products by Micro-grinding: A

2016年1月1日 Abstract Demand for complex structures and miniature features, especially on hard and brittle materials with a required surface finish, urges a significant

Strategies for production of parts textured by grinding

2013年1月1日 Strategies for production of parts textured by grinding using patterned wheels ScienceDirect Abstract Introduction Section snip References (7) Cited by

Part Processing by Grinding SpringerLink

This chapter describes some of the factors involved in process planning, illustrates the detailed knowledge required to perform typical precision grinding operations, and

Precision Metal Grinding Metal Cutting

2020年6月14日 Quality measures that can help the production process go smoothly; What are your options for grinding small metal parts? Precision metal grinding processes remove material from a workpiece to achieve

Grinding parts grindaix GmbH

The term "grinding" is understood to mean a production process in which the high-hard abrasive grains (cBN, corundum, SiC, diamond, etc.) in bonded form (grinding tools)

Four tips for mass-producing parts. UNITED GRINDING

2020年4月21日 Mass production is a simple idea: producing as many parts as possible to boost cost-efficiency and meet customer demands. In practice this simple idea quickly

parts grinding production

Parts Of Grinding Machine, Wholesale Various High Quality Parts Of Grinding Machine Products from Global Parts Of Grinding Machine Suppliers and Parts Of Grinding

Ultra-precision grinding ScienceDirect

2010年1月1日 Abstract. Ultra-precision grinding is primarily used to generate high quality and functional parts usually made from hard and difficult to machine materials. The objective of ultra-precision grinding is to generate parts with high surface finish, high form accuracy and surface integrity for the electronic and optical industries as well as for

Strategies for production of parts textured by grinding

2013年1月1日 Strategies for production of parts textured by grinding using patterned wheels ScienceDirect CIRP Annals Volume 62, Issue 1, 2013, Pages 355-358 Strategies for production of parts textured by grinding using patterned wheels Eraldo Jannone da Silva a,João Fernando Gomes de Oliveira (1) a,Bruno Barbosa Salles b,Ricardo Santoro

Ultra-precision grinding ScienceDirect

2010年1月1日 Ultra-precision grinding is primarily used to generate high quality and functional parts usually made from hard and difficult to machine materials. The objective of ultra-precision grinding is to generate parts with high surface finish, high form accuracy and surface integrity for the electronic and optical industries as well as for astronomical

±0.001mm Ultra Precision Grinding Services Company DEK

1 At DEK, we pride ourselves on ultra-precision technology and quality. Our capabilities in grinding start at 0.1mm up to 300mm in diameter, 2mm up to 1200mm in length with a tight tolerance as low as ±0.001mm (+/- 0.00005″), and a micro finish as low as 0.6ra. Don’t hesitate, we are your best partner for precision grinding services, contact

Strategies for production of parts textured by grinding

2013年1月1日 Strategies for production of parts textured by grinding using patterned wheels ScienceDirect Abstract Introduction Section snip References (7) Cited by (44) Recommended articles (6) CIRP Annals Volume 62, Issue 1, 2013, Pages 355-358 Strategies for production of parts textured by grinding using patterned wheels Eraldo

In-process detection of grinding burn using machine

2021年5月22日 The improvement of industrial grinding processes is driven by the objective to reduce process time and costs while maintaining required workpiece quality characteristics. One of several limiting factors is grinding burn. Usually applied techniques for workpiece burn are conducted often only for selected parts and can be time

Grinding parts grindaix GmbH

The increasing grinding performance resulting from this leads to greater mechanical and thermal wear on the grinding tools (e.g. grinding wheels) as well as to higher energy input into the rim zone of the part which, in the worst case, may result in thermal damage to the parts ( workpieces) in the form of microcracks or grinding burn, for instance.

(PDF) Powder Metallurgy Processes and Making

2020年10月26日 Powder metallurgy, which is an advanced production method, is a production method that allows the production of all technological parts, using very small parts, can be applied very...

Robotic Grinding for Surface Repair SpringerLink

2022年4月20日 Where \(\user2{ \alpha }\) is the coefficient of deformation and 1/k is the stiffness. In the spark out stage, the residual stock continues to be removed until the wheel is retracted as shown in Figs. 5, 6 and 7 were the grinding wheel is in contact with the workpiece. If the real depth of cut is \({{\varvec{\updelta}}}\) it should theoretically be cut

Rotary kiln system_Grinding equipment_Spare parts

2021年9月23日 The production process adopts advanced equipment such as efficient extrusion combined grinding system, DCS distributed automatic control system and large bag type dust collector. The main equipment is configured in a large scale, and the quality control means and facilities are complete, The quality is stable and reliable, which can

Grinding and fine finishing of future automotive

2021年1月1日 1. Introduction The automotive industry is the primary driving force behind advances in grinding and fine-finishing machines [250] and processes [85]. The demands for higher efficiency through downsizing and improvements of powertrain components lead to unprecedented performance in terms of reduced fuel consumption and emissions.

Ultra-precision grinding ScienceDirect

2010年1月1日 Grinding Finishing 1. Introduction During the last decades the demand for high precision parts has strongly increased. Such parts entered a wide range of applications in the optical, automotive, and communication industry as

Ultra-precision grinding ScienceDirect

2010年1月1日 Introduction During the last decades the demand for high precision parts has strongly increased. Such parts entered a wide range of applications in the optical, automotive, and communication industry as well as in medical and life sciences.

±0.001mm Ultra Precision Grinding Services Company DEK

1 Our capabilities in grinding start at 0.1mm up to 300mm in diameter, 2mm up to 1200mm in length with a tight tolerance as low as ±0.001mm (+/- 0.00005″), and a micro finish as low as 0.6ra. Don’t hesitate, we are your best partner for precision grinding services, contact us today! Get A Quotation

Grinding parts grindaix GmbH

The increasing grinding performance resulting from this leads to greater mechanical and thermal wear on the grinding tools (e.g. grinding wheels) as well as to higher energy input into the rim zone of the part which, in the worst case, may result in thermal damage to the parts ( workpieces) in the form of microcracks or grinding burn, for instance.

In-process detection of grinding burn using machine

2021年5月22日 The improvement of industrial grinding processes is driven by the objective to reduce process time and costs while maintaining required workpiece quality characteristics. One of several limiting factors is grinding burn. Usually applied techniques for workpiece burn are conducted often only for selected parts and can be time

Robotic Grinding for Surface Repair SpringerLink

2022年4月20日 where T being the remaining stock, T 0 being the initial stock, t is the contact time and τ is the time constant estimated of the grinding system. It is important to determine the number of infeed and spark-outs for each grinding pass. The selection of the optimum grinding cycle parameters depends on the knowledge of deflections

An Introduction to the Optics Manufacturing Process

2008年10月31日 the grinding process mechanically removes material by breaking off small pieces of glass, the polishing process is both mechanical and chemical. In this stage, the final For higher production parts, high speed CNC (Computer Numerical Control) machines can also be used. This process involves using synthetic pads and a variety of

Grinding mill parts Metso

In addition to supplying high-quality parts for Metso equipment, we also have a long history in servicing non-Metso machines, from grinding mills and crushers to conveyors and beyond. The Contender™ Series is our newest line of premium spare parts for non-Metso grinding mills. The line includes grinding mill heads, shells, gears and pinions

Rotary kiln system_Grinding equipment_Spare parts

2021年9月23日 The production process adopts advanced equipment such as efficient extrusion combined grinding system, DCS distributed automatic control system and large bag type dust collector. The main equipment is configured in a large scale, and the quality control means and facilities are complete, The quality is stable and reliable, which can

آلة تصنيع الرمل الصناعي للبيع مطحنة صانع

محطم صدمة مرنة سعر امتصاص

شركات تكسير الخرسانة في السلطة الفلسطينية

استخراج البوكسيت في جامايكا

ختم العنكبوت جلبة sfk 0 كسارة الأولية

طاحونة خام الرسم البياني

كيدوا كسارة راهانغ تانجان

الأخضر صناديق الشركات التابعة لها

كسارة الفك الهندي من قدرة صغيرة

تكلفة 200tph الحجر كسارة متنقلة في مصر

الة حلاقة بالحجر

كسارة منحنى سرعة المحرك وعزم الدوران

محرك لآلات الطحن

التطويرالاقتصادى فى والصناعة والتجا

تواجه الأدغال ذروة طحن

خرد کردن سنگ گچ به پودر

التعدين إقليم الذهب إكوادور

تكنولوجيا معالجة الهيماتيت

الاسمنت يحتوي على الأكسجين

تستخدم اكويبتمينت كسارة للبيع

سيور ناقلة تجار الجملة وتجار

الفك محطم يوركشاير تأجير

دليل تكنولوجيا مسحوق حبيبات

معدلات الهند الصخور آلة الصالة الرياضية

چرخ قبر پورنو سخت کار کردن

محجر البازلت في مصر

حول لدينا

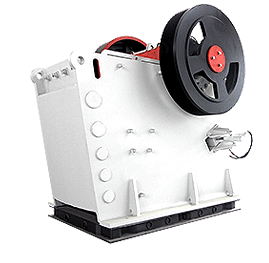

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20