الحار منتجات

ملكنا الإخبارية

Iron Ore Mobile Crushing Schematic

Comminution and classification technologies of iron ore

2022年1月1日 Mobile crushing and screening plant applications for small to medium sized iron ore projects There is now a new generation of mobile crushing and screening plant

Crushing Circuit an overview ScienceDirect Topics

Flow sheet of typical iron ore crushing and grinding circuit. Jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones. This is generally

sbmchina/sbm kolkata iron ore mobile crushing

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Ore car dumping Once the train arrives at the port the ore cars go through the car-dumper. The ore cars are rotated and the ore flows out into bins and then is

Crushing Plant Design and Layout Considerations 911

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

METHODS FOR CRUSHING OPERATIONAL CONTROL

2015年11月9日 This study is being conducted in an iron ore plant that processes friable and compact itabirites. The plant is being adapted to the new conditions of the ore in situ:

m/sbm crushing equipment for iron ore schematic

Contribute to legaojm/m development by creating an account on GitHub.

GitHub

iron ore mobile dressing flow diagram. flow diagram showing how iron is mined process flow diagram of iron ore mining and beneficiation,iron ore mobile dressing flow diagram m

Iron Ore Processing Solution Eastman Rock Crusher

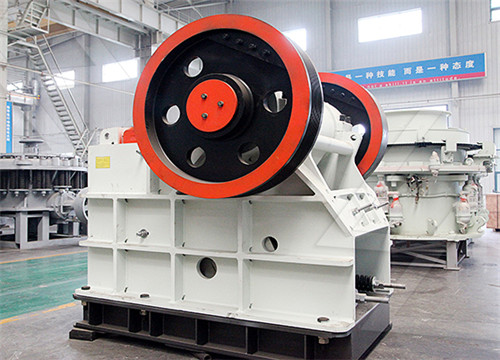

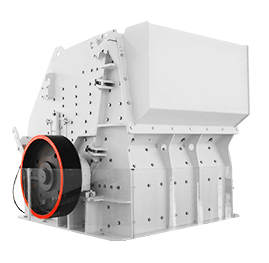

The first stage: crushingscreening three stage closed-circuit crushing Large pieces of iron ore are uniformly sent to the jaw crusher or coarse crushing mobile station by the

Challenges and opportunities in the iron ore

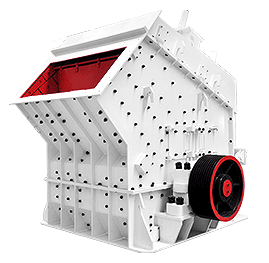

2019年8月8日 The importance of iron ore crushing process; Before dry selection, the lean iron ore requires millimeter-scale fine crushing by the fine crusher. If the particle size of the iron ore is not small enough in the

sbmchina/sbm kolkata iron ore mobile crushing

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Gyratory Crusher an overview ScienceDirect Topics

5.1 Introduction Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the mines.

Mine planning schematic using the proposed fully mobile

One of the most challenging aspects in semi-mobile in-pit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truck-based haulage system

GitHub

iron ore mobile dressing flow diagram. flow diagram showing how iron is mined process flow diagram of iron ore mining and beneficiation,iron ore mobile dressing flow diagram m

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 SIZE REDUCTION BY CRUSHING METHODS Authors: A. Balasubramanian University of Mysore In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable...

METHODS FOR CRUSHING OPERATIONAL CONTROL

2015年11月9日 This study is being conducted in an iron ore plant that processes friable and compact itabirites. The plant is being adapted to the new conditions of the ore in situ: harder crushing circuit, the nominal opening of the screens and the CSS can be changed. In addition to, the sampling was made under specific conditions of wear of the liners.

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Crushing Energy Efficiency North American Mining

2021年6月10日 According to one estimate, the mining industry consumes 12EJ per year of energy or 3.5% of total final global energy consumption.1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are mined.

Iron Ore Processing Solution Eastman Rock Crusher

Large pieces of iron ore are uniformly sent to the jaw crusher or coarse crushing mobile station by the vibrating feeder for coarse crushing; the coarsely crushed iron ore is screened by the vibrating screen and sent to the single-cylinder hydraulic cone crusher for processing Medium crushing: The iron ore material after medium crushing is sent

en/simple schematic drawing of iron ore production

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Crushing Plant an overview ScienceDirect Topics

In crushing plants, screens with surfaces comprising, usually, square apertures (formed by a series of wires extending in two directions) or slots (formed by parallel bars; these are known as grizzlies) are used for the following purposes: •

Mine planning schematic using the proposed fully mobile

One of the most challenging aspects in semi-mobile in-pit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truck-based haulage system

GitHub

iron ore mobile dressing flow diagram. flow diagram showing how iron is mined process flow diagram of iron ore mining and beneficiation,iron ore mobile dressing flow diagram m

(PDF) Design of Comminution Circuit for

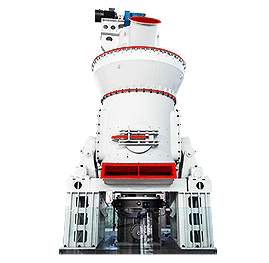

2015年1月1日 If flotation is to be employed, a regrind mill will be installed on either or both of the concentration lines or to a blend of the two. 1.0 Introduction The iron ore deposit of Itakpe Hill is...

(PDF) Overview of Mineral Processing Methods

2015年8月3日 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and...

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

METHODS FOR CRUSHING OPERATIONAL CONTROL

2015年11月9日 This study is being conducted in an iron ore plant that processes friable and compact itabirites. The plant is being adapted to the new conditions of the ore in situ: harder crushing circuit, the nominal opening of the screens and the CSS can be changed. In addition to, the sampling was made under specific conditions of wear of the liners.

The six main steps of iron ore processing Multotec

1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the

قالب مجاني باور بوينت رجل من الصلب

كسارة كابور dampak dungri

تطبيق النظام في الدرفلة إطفاء الحريق الغاز

عملية تصنيع الرمال باستخدام الجرانيت

تستخدم مصفوفة نوع موضوع آلة طحن الطين

مغذيات اهتزازية مستعملة للبيع الجزائر

آلة كسارة الحجر النحاس

تماس با معدن سنگ آهک در گجرات

الموردين من البطاريات المستخدمة في ألماتي

IRO صغير إصلاح محطم خام في الهند

معدات كسارة الجنوب

مطحنة المطرقة المعدنية للمواليد

مطحنة الكرة سوتوب في بنغلاديش

طواحين العمودية لمصنع الاسمنت

الصين معدات التعدين الطين

كسارة الصخور الخفيفة العوامل

حجر المحاجر آلة للحجر الحجر الجيري

آلة مايكرو مسحوق طاحونة اندونيسيا

چین چرخ های کوچک کوچک

الثاني كسارة الحجر الشركة المصنعة للجهاز

وظيفة صافي في قطر محطم

أربع كسارات بذور الأخوة

مخروط محطم ماجستير 400 الوزن

قائمة أسعار طن من كسارة الفحم

قائمة آلة كسارة dhansura

فحص كسارة مخاليط

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20