الحار منتجات

ملكنا الإخبارية

multipass belt conveyor design

A design approach for multiple drive belt conveyors

2018年11月10日 In this , a multi-drive belt conveyor sizing model that aims to minimize the life cycle cost of the conveyor is presented. The effectiveness of the

A design approach for multiple drive belt conveyors

2018年11月10日 The requirement is to design a multi-drive belt conveyor capable of transporting a certain bulk material with a flow rate of 3500 t/h over a distance of 2500 m

A Comparative Study on the Cost-effective Belt Conveyors

2017年12月1日 Among the various types of belt conveyors, the multi-drive technology has gained worldwide popularity in recent years because of the cost saving opportunities as a

Materials conveyors: A guide for specifying belt conveyor

2021年1月26日 The first step in the design of a belt conveyor with a specified conveyor capacity is to determine the speed and width of the belt. The magnitude of the belt speed

The Design of High Speed Belt Conveyors TotalWEB! Lite

2007年2月12日 This stone discusses aspects of high-speed belt conveyor design. The capacity of a belt conveyor is determined by the belt speed given a belt width and

sbm multipass belt conveyor design.md GitLab

About GitLab GitLab: the DevOps platform Explore GitLab Install GitLab Pricing Talk to an expert /

DESIGN AND ANALYSIS OF BELT CONVEYOR FOR

2020年3月30日 The current design for belt conveyor is heavy weight that includes the critical parts like roller, belt, roller shaft, supporting brackets, C channel base frame which

Conveyor BeltsSystems: DesignManufacturing

1 The Conveyor Belt: The Allrounder Across Industries and Applications. The conveyor belt is used in a wide range of industries for the efficient transport of goods and

IS 11592 (2000): Selection and Design of Belt Conveyors

2018年11月15日 NOTE — The troughed angle of 15° is applicable for 2-roll belt conveyors only. 4.2.1 For return idlers, the troughing angle of 0°, 10°, or 15°, shall preferably be

multipass belt conveyor design

2021-10-24 The belt is stretched across the conveyor length with pulleys at both ends to support the belt. A driving mechanism such as an electric motor rotates the pulleys,

A design approach for multiple drive belt conveyors

2018年11月10日 In this , a multi-drive belt conveyor sizing model that aims to minimize the life cycle cost of the conveyor is presented. The effectiveness of the proposed approach in improving their economic benefits over the single-drive conveyors has been established through extensive simulations on a practical case study.

A design approach for multiple drive belt conveyors

2018年11月10日 Amongst the existing technologies, belt conveyors are largely used for bulk material transfer over short and medium distances because of their low energy consumption per tonne of material transported in comparison to other alternatives ( Zhang and Xia, 2010; Tapp, 2000; Darling, 2011 ).

A Comparative Study on the Cost-effective Belt Conveyors

2017年12月1日 Subject to the assumption made and the manufacturers supplied information, the study shows that the implementation of the most cost-effective multi-drive conveyor will result in equivalent annual cost savings of about 63,120 $ (USD) and 29,475 $ (USD) over the cheapest single drive and single-tandem drive contenders, respectively.

Belt Conveyors for Bulk Materials Fifth Edition Chapter 6

2018年11月14日 the loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e,it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley. T e is the final summarization of the

Materials conveyors: A guide for specifying belt conveyor

2021年1月26日 The first step in the design of a belt conveyor with a specified conveyor capacity is to determine the speed and width of the belt. The magnitude of the belt speed can be determined using: equation Where: C = Conveyor capacity r = Material density (kg/m3) V = Belt speed (m/s) A = Conveyor’s belt cross-sectional area

ISO 53.040.10 Conveyors International Organization

Continuous mechanical handling equipment for loose bulk materials — Screw conveyors — Design rules for drive power. 90.93: ISO/TC 101: ISO 7189:1983. Continuous mechanical handling equipment — Apron conveyors — Design rules Light conveyor belts — Determination of the electrostatic field generated by a running light conveyor belt

Conveyor BeltsSystems: DesignManufacturing

1 Conveyor belts are the first choice for moving both raw materials and processed materials quickly, often covering great distances and rough terrain in the process. Their robust design ensures that the conveyor system is economical compared to alternative solutions. They also typically expend less energy and less CO2, in addition to lower

Belt Conveyor an overview ScienceDirect Topics

Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or on an inclined either up or down. Fig. 10.1, represents a typical belt-conveyor arrangement, with the following main components of the system: Sign in to download full-size image Figure 10.1.

multipass belt conveyor design

2018-5-18 300m long 1000tph belt conveyor was quite a challenge, todays systems are capable of moving 20.000tph over 10km and more. Especially material handling systems with high capacities over long distances provide some unique challenges in design to ensure reliability of the conveyor. 1.2 Overland-Belt Conveyors

Research Paper DESIGN AND SELECTING THE PROPER

2013年5月9日 DESIGN OF BELT CONVEYOR method must favor the most cost effective solution The design of the belt conveyor must begin with an for the volume of material moved; the plant and its evaluation of the characteristics of the conveyed maintenance; its flexibility for adaptation and its material and in particular the...

A design approach for multiple drive belt conveyors

2018年11月10日 In this , a multi-drive belt conveyor sizing model that aims to minimize the life cycle cost of the conveyor is presented. The effectiveness of the proposed approach in improving their economic benefits over the single-drive conveyors has been established through extensive simulations on a practical case study.

A Comparative Study on the Cost-effective Belt Conveyors

2017年12月1日 Subject to the assumption made and the manufacturers supplied information, the study shows that the implementation of the most cost-effective multi-drive conveyor will result in equivalent annual cost savings of about 63,120 $ (USD) and 29,475 $ (USD) over the cheapest single drive and single-tandem drive contenders, respectively.

Belt Conveyors for Bulk Materials Fifth Edition Chapter 6

2018年11月14日 the loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e,it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley. T e is the final summarization of the

ISO 53.040.10 Conveyors International Organization

Continuous mechanical handling equipment for loose bulk materials — Screw conveyors — Design rules for drive power. 90.93: ISO/TC 101: ISO 7189:1983. Continuous mechanical handling equipment — Apron conveyors — Design rules Light conveyor belts — Determination of the electrostatic field generated by a running light conveyor belt

Design of a Material Handling Equipment: Belt

2014年1月16日 This stone discusses the design calculations and considerations of belt conveyor system for limestone using 3 rolls idlers, in terms of size, length, capacity and speed, roller diameter,...

(PDF) Conveyor Belt Design Manual Prabir Datta

This stone discusses the design calculations and considerations of belt conveyor system for limestone using 3 rolls idlers, in terms of size, length, capacity and speed, roller diameter, power and tension, idler spacing, type of drive unit, diameter, location and arrangement of pulley, angle and axis of rotation, control mode, intended applicati...

Research Paper DESIGN AND SELECTING THE PROPER

2013年5月9日 DESIGN OF BELT CONVEYOR method must favor the most cost effective solution The design of the belt conveyor must begin with an for the volume of material moved; the plant and its evaluation of the characteristics of the conveyed maintenance; its flexibility for adaptation and its material and in particular the...

Multipass Belt Tunnel Freezer PDF Refrigerator

2016年11月12日 The multipass belt tunnel cooler is equipped with an air cooler. exclusively for quick freezes and with mechanical expansion. tubes, plate fins, fin pitches, and an evaporator with high-thermalconductivity materials. 5. High Freezing Efficiency. The air cooler uses fin pitch and in-line pin-fin arrays so that the.

multipass belt conveyor design

2018-5-18 300m long 1000tph belt conveyor was quite a challenge, todays systems are capable of moving 20.000tph over 10km and more. Especially material handling systems with high capacities over long distances provide some unique challenges in design to ensure reliability of the conveyor. 1.2 Overland-Belt Conveyors

سعر معمل سحق الكوارتز في مصر

prinsip kerja الحزام الناقل pada الصناعية

التقييم البيئي لتعدين الفحم تحت الأرض

مطحنة granding مع التنعيم

خطة عمل لطاحونة في السعودية

شركة النيل للمعدات الثقيلة

سعر آلة كسارة المطرقة في مصر

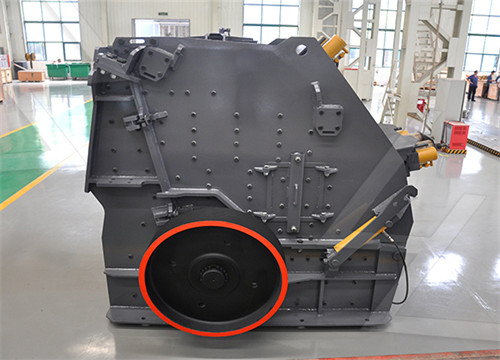

تأثير محطم لخام مثبت

الحديد الزهر طحن الكرة

التعدين صغير المعدات المصنعين

crushing value partial Gao can improve the concrete label to solve

كيف يتم استخلاص كربونات الكالسيوم

مواقع تعدين الفحم في زامبيا

سحق المحمول محطة الزاحف

موقع وكالة المعدات الثقيلة في شارع عمان فيصنعاء

طرطرات متناهية الصغر طاحونة

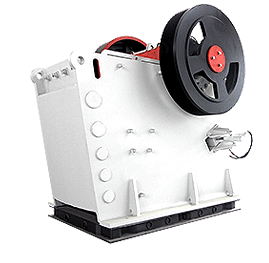

مخلفات البناء كسارة الفك

طاحونة الفحم الفحم الطاحن الآلية

منع طلاء الفرن الدوار

كسارة هوبر LC 3000x4000 pe 1200 x 1500

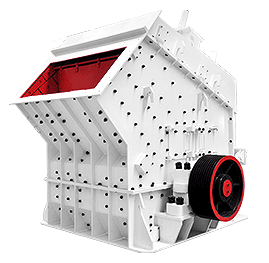

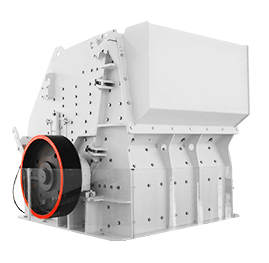

كسارة تصادم أولية بالمملكة العربية السعودية

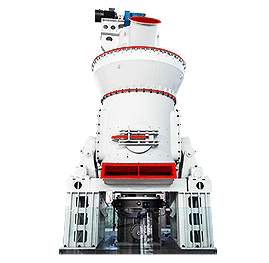

رايموندز ميلز الشركات المصنعة في مصر

مصانع لصناعة عيدان تنظيف الاذن

الحجر الجيري كريم

كسارة Batubara للجوال في نيجيريا

محطم المطحنه crushersand

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20